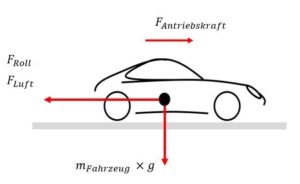

Basically there are two main driving resistances that prevent us from going infinitely fast: the rolling resistance FRoll and the air resistance FAir. Two forces that act against the driving force of the vehicle on a flat road and literally slow down the car.

Source: Wikipedia (https://bit.ly/2EVmSyR)

The mode of action of these resistors depends strongly on the speed of the vehicle. If you move at approx. 30 km/h, the influence of the rolling resistance is approx. 90% and that of the air resistance only approx. 10%. So you could also drive with a wall unit on the roof of your car and would not have a much higher fuel consumption. Provided the wall unit is light.

At a speed of approx. 100 km/h the influence of air resistance is already a remarkable 63%, at 160 km/h already 81%. At even higher speeds the driving force of the vehicle practically only fights against air resistance.

In order to develop a roof box that does not negatively affect the performance of the vehicle even at high speeds, an aerodynamic shape is essential.

Contact pressure

Especially sporty vehicles generate contact pressure due to their design. Although this increases fuel consumption, the force acting perpendicular to the road increases performance in curves and improves safety. This is a factor that should not be underestimated, especially for vehicles in the high-performance segment.

Fun Fact: A Formula 1 car generates so much downforce at high speed that if you turn the track upside down it would still “stick” under the asphalt.

So far so good. We have taken Mother Nature as our model for implementation, because nature is the best advisor when it comes to efficiency. Over millions of years of evolution, nature has adapted perfectly to its environment. In the meantime, this tip has also arrived in the world of engineering. So it is no coincidence that a penguin with the shape of a drop has the perfect aerodynamic shape.

Result

The result is impressive: an optimised roof box, Made in Germany, without having to make any compromises. Built from CO2 neutral high-end natural fibres. Developed to create a perfect symbiosis between car and roof box.

Source: CFD support (https://bit.ly/3lKLpro)

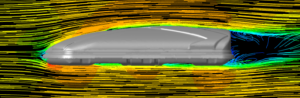

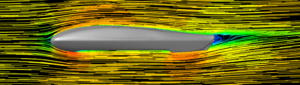

The Cw-value of the ASPHALTKIND roof box is approx. 0.11 and is therefore approx. 30% lower than that of conventional roof boxes. Doesn’t sound like much at first. However, it should be noted that the geometric design generates downforce and not lift as with conventional roof boxes. Written in numbers, the roof box pushes the vehicle vertically onto the road at a speed of 160 km/h with approx. 110 N (approx. 10kg). In comparison: a conventional roof box pulls the vehicle slightly upwards. This provides less traction when driving on the motorway and therefore represents an increased risk of accidents, especially on wet roads. The result can be illustrated as follows:

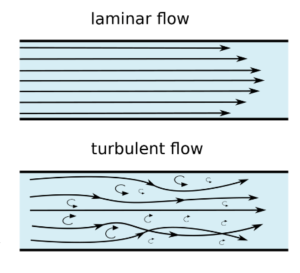

Conventional roof box with large dead water area (black spot)

Conventional roof boxes show a high turbulent intensity (turbulent = bad) in the rear area. This results in a large so-called dead water area, which takes up approx. 1/3 of the roof box length, before the streamlines converge again in laminar (laminar = good). Such turbulent effects have a negative impact on the performance of the roof box and cause an increased fuel/energy consumption due to the negative pressure that is created.

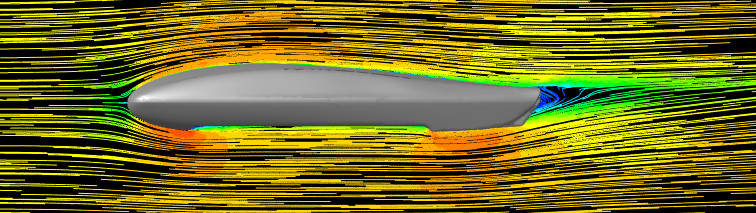

ASPHALTKIND roof box with significantly smaller dead water area

With the ASPHALTKIND roof box, the aerodynamic drop shape results in significantly lower flow separation in the rear area and thus also in a significantly reduced fuel consumption/energy consumption. The result is a much more homogeneous flow model with a pronounced laminar course. Just like a penguin.